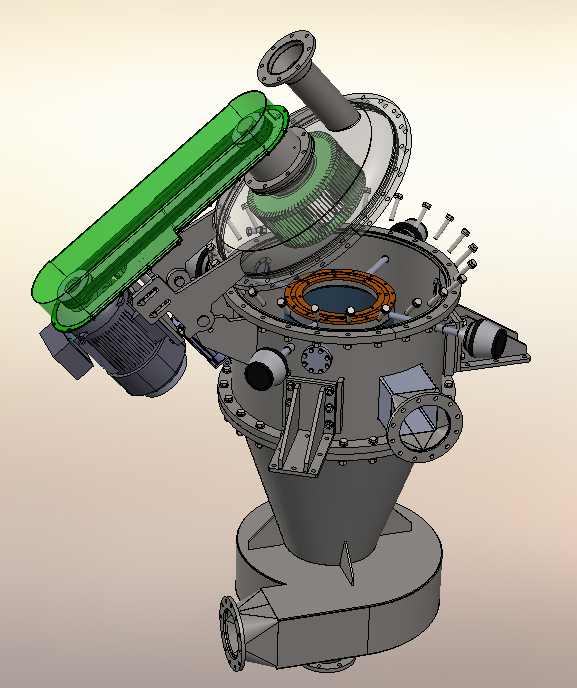

Air Classifier CDC

The properties of powdered materials are often determined by their fineness and their particle size distribution. Often these parameters can not be reliably controlled during the production process. In many cases, the required properties can be achieved by a subsequent classification. The CDC fine air classifier achieves optimum separation accuracy with the highest material load. Both coarse material as well as for fines removal are guaranteed in the usual range of application of approx. 5 µm - 100 µm (d90).

Resulting from the hanging configuration of the classifying rotor, the air rises to the classification zone where it uniformly enters the rotor. Thereby a very sharp separating curve can be achieved. Ultimately, this results in lower rotor RPM as well as lower air flow. Due to the hinged design of the closure head the classifier, an easy access to the classifying rotor and fines outlet is possible.

Proven unicycle design

• Symmetrical design for uniform material loading and better performance

• Only one gap between the sight wheel and the fixed housing

• Only one bearing and one drive

• Easy access to cleaning and maintenance

Advantages for the operator:

The material to be classified is injected separately via a feed pipe on the cover of the separator housing or via the inlet together with the classifying air. The product is dispersed at the lower end of the machine by the classifying air which flows into the classifier at high speed through a spiral housing. The separation of the feed material into fine and coarse material takes place via a classifying rotor which can be adjusted. Which particle sizes are passed through the rotor can be adjusted by the parameters air flow and Rotor RPM. The fines leave the classifier via the rotor through the fine outlet. The fine particles are transported away pneumatically and subsequently deposited by cyclone separator or bag filter. Coarse particles are rejected by the rotor and discharged on the underside of the housing.

Versions:

• Housing - pressure resistant, up to 10 bar

• Housing - different materials depending on application: steel, stainless steel, ceramics, surfaces treated or polished, wear protection.

• classifying rotor - various geometries (optimized for internal classification)

Applications

The CDC fine classifier is used when the operation of screening machines is no longer possible due to the separation limit. This can be the case with fine particle sizes or with particles with an inhomogeneous geometrical shape. In addition, the productivity of screening machines with fine particle sizes decreases greatly as a result of the decreasing transmittance.

• Separation of fines (e.g. dust removal from toner)

• Separation of coarse fraction (standard application)

• Separation of product-specific product fractions (e.g. protein shift)

• Separation of geometry-specific product fractions (e.g. pigments)

• De-agglomeration

• Drying due to low temperature increase

Benefits

• Modern classifying rotor with lowest cut size

• Exactly defined, sharp cut size

• High process reliability thanks to robust design, proven over many years

• Air purge of gap between the classifying rotor and housing prevents oversize particles in the fine fraction.

• Hinged closure head minimizes service and cleaning time

Specific Design Features

• Air purge of bearing of the classifier’s rotor

• Air purge of the sealing gap between the rotor and classifier’s housing

• Sensors for monitoring the bearing’s temperature and vibration

• automatic permanent lubrication of the bearings