Filtration & Environment

The HydroTower wet scruber - wet separators are predestined for the deposition of solid or gaseous substances which can not be deposited in a dry process or are difficult to deposit. The gas stream is brought into contact with a liquid stream (such as water, suspensions such as lime milk) to absorb components of the gas stream in the liquid. By means of the wet separator, harmful gases (aerosols small 1 µm) can be deposited simultaneously with the dedusting. In this case, a drop separator of the type ABZ will also be connected downstream.

The wet dust extractor comprises three unit sizes for cleaning / dedusting gas volumetric flows from 2'000 m3 / h to 6'000 m3 / h. As one of the few devices on the market, the HydroTower wet separator is made entirely of stainless steel. It has a high resistance against aggressive raw gases and is protected against rusting.

Separation:

• liquid separation:

99,5 % for droplets of the sizes 8 – 10 um

• particles separation:

99,9 % for particles up 5 um

Pressure loss:

Since the pressure losses depend strongly on the gas properties, as well as on the thermodynamic characteristics of the process, the pressure loss is calculated individually for each application.

Options:

Material: Stainless steel 1.4301, 1.4541 or 1.4571, matte stained.

Construction according to AD 2000 regulations or other regulations.

Acceptance: TÜV

Flanges according to DIN 2633 or DIN 2632

Benefits

• universal use

• safe in case of fire and explosive dusts

• High degree of separation in safe operation

• modular construction - saving space and low maintenance

• No use of filter elements

• Compliance with TA-Luft

• Compliance with the BG guidelines BGR104 / 109/204

Dedusting

• Safe separation of explosive, ignitable and incandescent dusts in wet wash processes

• Dust removal of damp, condensing exhaust gases

• Deposition of oily, sticky products

Function

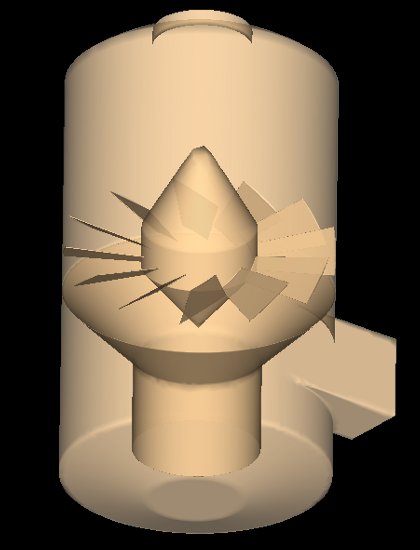

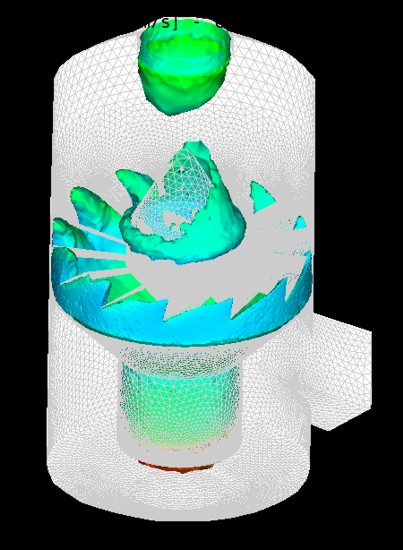

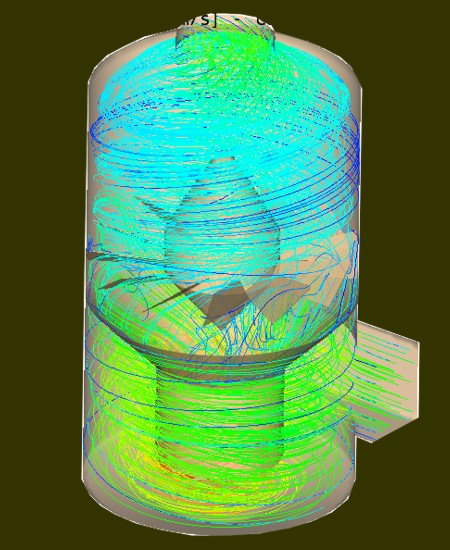

The polluted and contaminated air enters tangentially into the middle part of the wet separator. The air guide creates a strong water vortex, which must pass the loaded raw gas. The dust particles contained in the air stream are surrounded by water due to the strong turbulences, so that even dust which is difficult to mix is ??bound. The water absorption of the dust particles increases their mass and thus the separation efficiency. The pollutant particles are intensively mixed with water and thrown against the inner wall in the water chamber. Strong rotation in the downstream separator housing separates the remaining water droplets according to the centrifugal force principle from the air stream. The purified air flows to the centrifugal fan via a demister or filter cartridge. This results in a high degree of separation. The particles deposited on the inner wall flow back into the lower part of the appliance with the wash water through the immersion tube.

The separated dust sediments and is collected as a sludge in a built-up, removable disposal tank. At certain intervals, this container must be emptied when the system is at a standstill. The sludge can be flushed out through a drain cock without having to replace the entire water volume.

The wet separator has a water leveling box with level control, fresh water fitting and overflow protection. If the water level falls below the specified setpoint level, the solenoid valve is opened in the fresh water mixer via the level regulator and water is fed until the setpoint level is reached.

Speed